BALMER LAWRIE AND COMPANY LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BALMER LAWRIE AND COMPANY LTD.

Composite Repair Services

Our wide range of Composite Repair services are designed to effectively take care of external corrosion related repair & maintenance needs in the Oil & Gas Production and Distribution sectors, chemical plants, Ports & plants in coastal areas, where corrosion is a primary threat.

The Service being provided is in association with IMG composites, UK, a leader in composite repair services & having experience in working with leading Oil & Gas companies across the globe.

Services

Our wide array of offerings include the following

Pipeline Repair Services

Vessel Repair Services

Emergency repairs in running plant.

Benefits

In-Situ repairs.

Minimal plant downtime

Flexibility of repairs.

High durability

Lifetime upto 15 years

Tank Bottom Sludge Processing

Home >

Services >

Tank Bottom Sludge Processing

Services

Composite Repair Services

Lagoon Sludge Processing

Tank Bottom Sludge Process

Sign Up For Updates

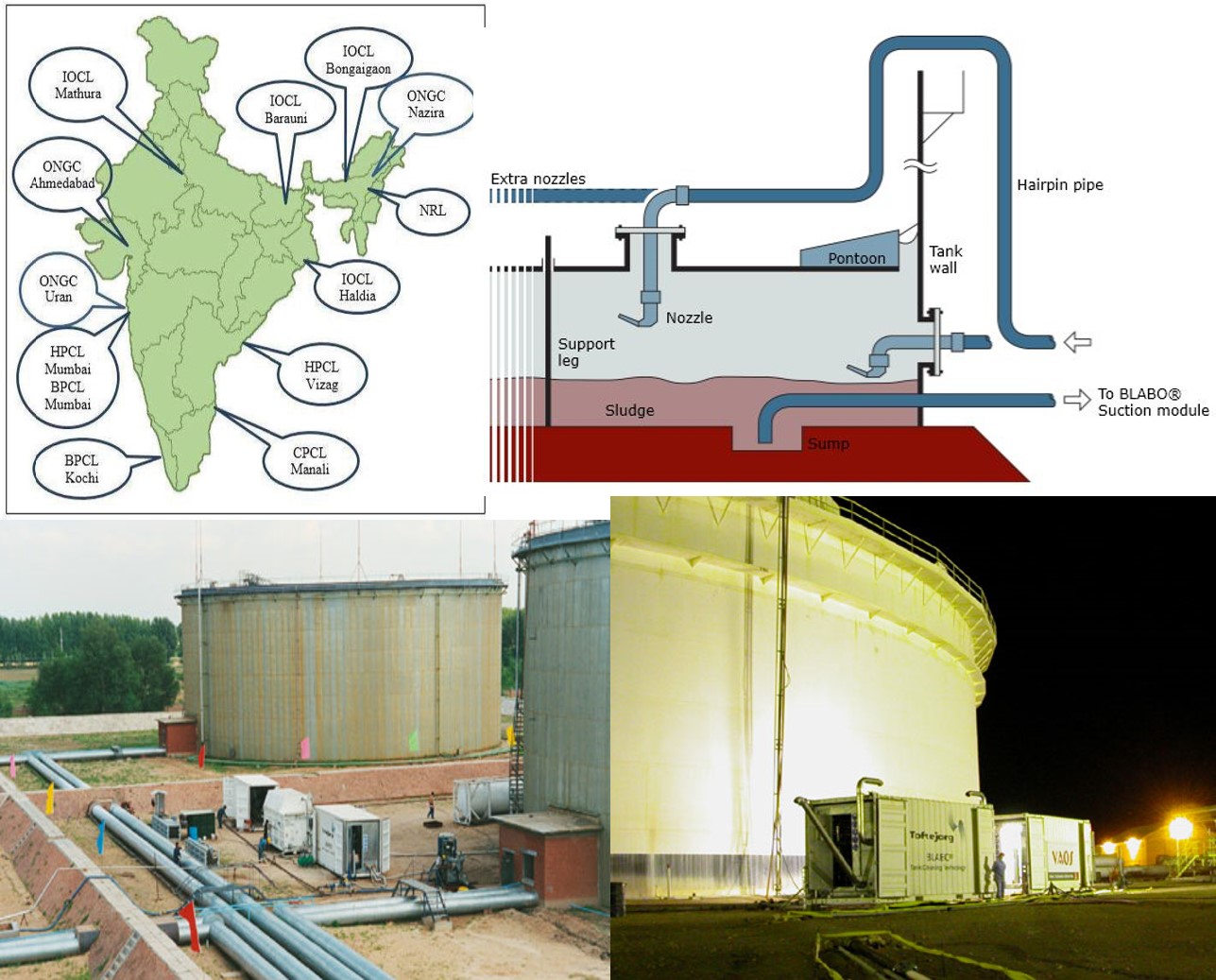

TANK BOTTOM SLUDGE PROCESSING

Our services in the scope of Tank Bottom Sludge Processing & Hydrocarbon Recovery are designed to effectively take care of oily sludge related tank maintenance problems & at the same time, create a substantial value addition opportunity through maximum recovery of trapped hydrocarbon.

Our BLABO process, in association with ORECO, Denmark uses state of the art technology to ensure maximum hydrocarbon recovery, reduced processing time along with utmost compliance to HSE & environmental norms.

Applications:

Oil Refineries.

Oil Installation Assets.

Power Plants.

Benefits:

Guaranteed recovery of up to 90% hydrocarbon content from oily sludge

Up to 60% reduction in tank cleaning time

Environment friendly process

No HSE Risk

Easier tank maintenance after cleaning

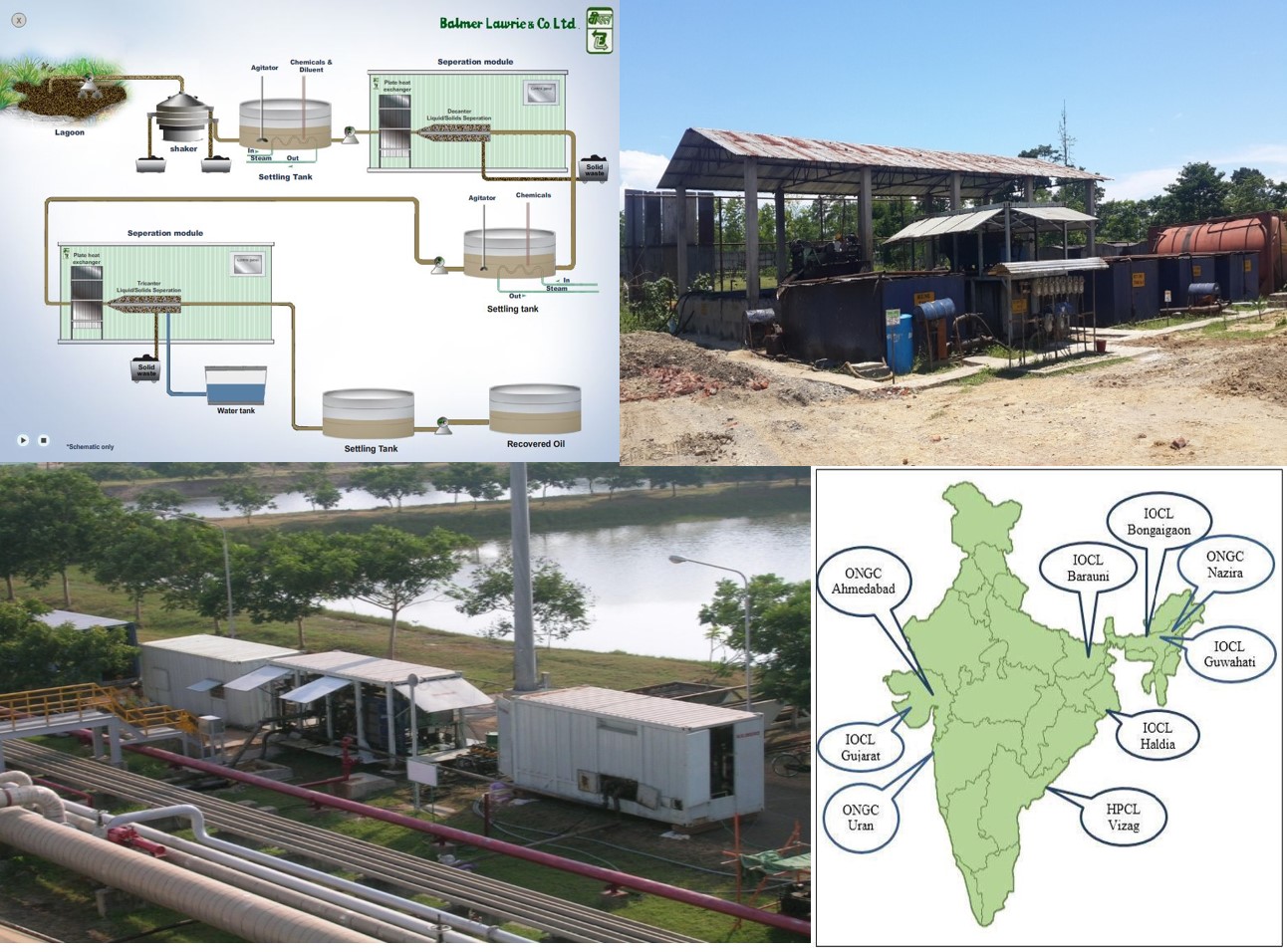

Lagoon Sludge Processing

Our Services for lagoon sludge processing, are designed to effectively tackle the potentially hazardous environmental pitfalls associated with lagoon sludge, ensuring maximum recovery of hydrocarbon & eliminating pollution & HSE issues at site.

BL has developed & adopted a technically advanced method for Lagoon Sludge Processing. The technology is being constantly upgraded & improved upon to enhance efficiency.

We have emerged as forerunners in this field, having processed over 70,000 Kilo Liters of Lagoon Sludge in Refineries, in last 6 years.

Benefits:

Maximum recovery of hydrocarbons

Reduced Processing time.

Environment Friendly Process

No HSE Risk

No Housekeeping Problems

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.